Robotic Arm

To better understand our Robotic Arm project a basic understanding of the components and movement of industrial robotics is required. To better understand industrial robotics study the article by Kawasaki Robotics in the link below.

https://robotics.kawasaki.com/ja1/xyz/en/1804-03/

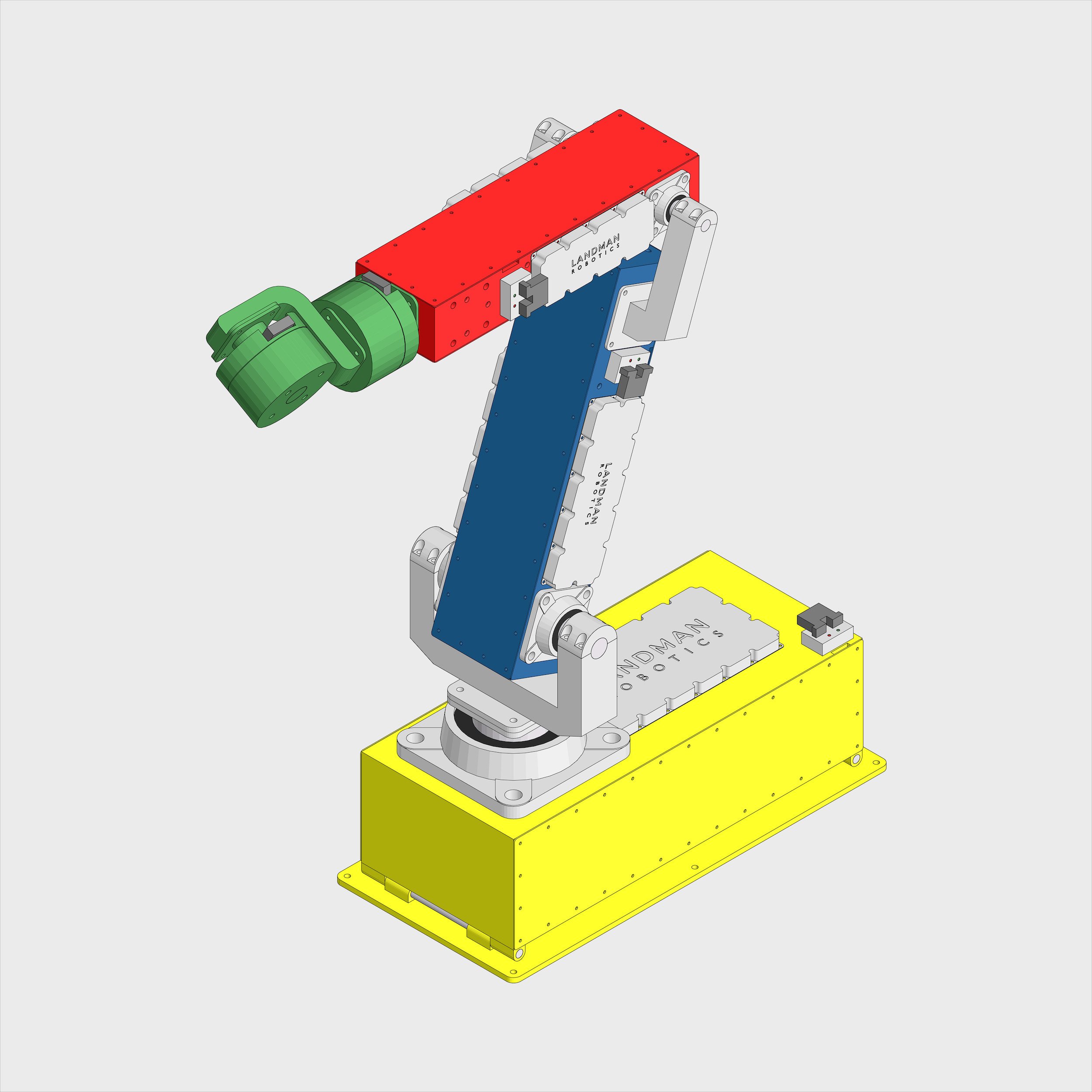

A robotic arm is a system comprising a series of Major Components (MC) working together in unison to execute a specific task. Our robotic arm can be subdivided into 4 MCs namely the Wrist Actuator (WA), Forearm Actuator (FA), Upper-arm Actuator (UA), and Rotary Actuator (RA).

We are in the process of designing and developing all four of these MCs. We have already produced a working prototype of the Forearm Actuator (FA), namely ADM3, and proved in a series of tests that ADM3 complies with our strict baseline specification as stipulated in the Forearm Actuator project section.

Developing the other MCs will be a relatively straightforward task. It will entail a repackaging exercise of the MC developed by us in the FA project. In short, the work executed in developing the FA will be extended to include the WA, UA, and RA to form our first complete robotic arm. Development of these components we estimate will start beginning of 2025.

Ultimately, we would like to produce a range of low-cost robotic arms capable of payloads in the range of 1 to 500 kg and reach in the range of 1 to 10 meters. Naturally, we will use the MCs developed in-house as this would drastically reduce costs and result in a series of low-cost robotic solutions.